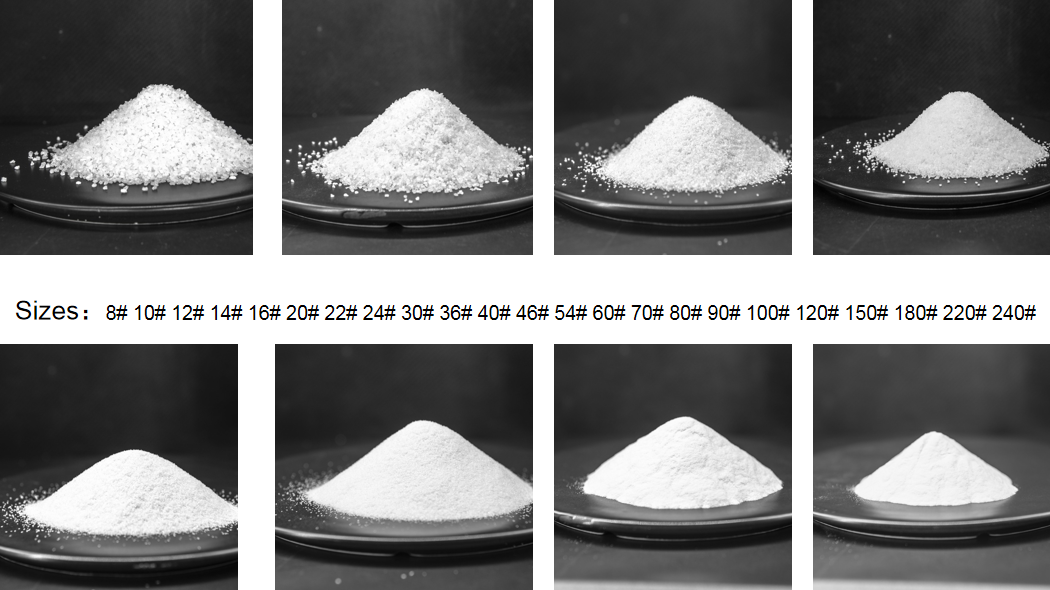

0.8micron 1micron White Fused Alumina

White fused alumina is a white abrasive made from industrial alumina powder (Al2O3) with a content of over 98% and a small amount of iron oxide and silicon oxide. It is a white abrasive which is melted at high temperature. Its hardness is slightly higher than that of brown corundum and its toughness is slightly lower. It is made by smelting and cooling above 2000 degrees in arc, grinding and shaping, removing iron by magnetic separation, and sieving into many kinds of granularity. It is compact in texture, high in hardness and sharp in shape.

Aluminum oxide is used successfully for cleaning, deburring, surface finishing, rust removal and old paint coatings, preparing surfaces for subsequent anti-corrosion treatments with paint and primer at the highest quality standards.

| Purpose | Specification | Chemical Composition(%) | Magnetic material content(%)max | ||||

| Abrasives grade | Al2O3min | Fe2O3max | SiO2max | TiO2max | |||

| grain | 12-80# | 99 | 0.05 | 0.26 | 0.08 | 0.0023 | |

| 90-150# | 99 | 0.06 | 0.28 | 0.09 | 0.0021 | ||

| 180-220# | 99 | 0.08 | 0.30 | 0.10 | 0.0018 | ||

| micropowder | 240-10000# | 98.5 | 0.1 | 0.40 | 0.15 | – | |

| Refractory grade | Group Size | 0-1mm 1-3mm 3-5mm 5-8mm | 99 | 0.1 | 0.35 | 0.3 | – |

| Fine Powder | -100mesh -200mesh -350mesh | 99 | 0.1 | 0.35 | 0.3 | – | |

| color | white | ||||||

| Hardness(mohs) | 9.0 | ||||||

| Melting point(°C) | 2250 | ||||||

| Maximum service temperature(°C) | 1900 | ||||||

| Ture density(g/cm3) | 3.9 | ||||||

White corundum powder application:

1.For precision casting and high-grade refractory.

2. For bake lining ,Catalyst carrier ,friction products

3.For pressure blasting hard abrasives;Refractory industry

4.For wet and dry blasting ,grinding,lapping and polishing media

5.For abrasive tools: grinding wheel, Lapping and polishing non-skid title;

6.For bonded and Coated abrasives ,Thermal Spraying (Plasma Spraying)

7.For lapping & Micro-Blasting applications .refractories,Ceramics and Tiles .

Reviews

There are no reviews yet.