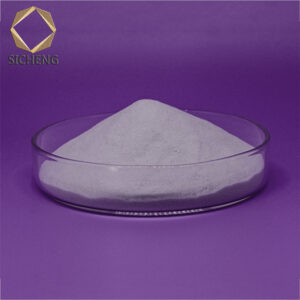

White fused alumina/White corundum is widely used in the industrial field because of its good hardness and strong wear resistance, especially white corundum micropowder, also known as white corundum powder. Although its price is high, the use of white corundum micropowder is wide, even it involves the aerospace field, so what are the production processes of white corundum micropowder?

1. Crushing: Put a set of hardened steel balls of different diameters into the drum together with the raw materials. After adding water, put in a rubber pad and seal the lid, and then rotate the drum. Under the impact of the steel ball, the abrasive will be crushed. Usually, when crushing 1kg of raw materials, the total weight of the required steel balls is about 3kg.

2. Pickling and washing: The main purpose of pickling and washing is to remove iron impurities in the abrasive.

3. Sorting: White corundum micropowder separation is carried out by using a water separation method in a glass cylinder. The weight ratio of water to white molten alumina powder is between 10:1 and 16:1.

4. Drying: Dry in a drying oven at 100-200℃. After drying, use a glass pestle or a horn spoon to crush the remaining agglomerates.

5. Satin Burning: Put the white corundum micro powder fused alumina powder into an electric furnace or Mafu furnace and raise it to 850 degrees at room temperature. For some white particles of white particles, sometimes it can reach 1200 degrees, and then keep it for 5 hours.

6. Soaking: When the abrasive is used for grinding and fine polishing, it needs to be immersed in the abrasive. The soaking requirement is to add 0.4 grams of stearic acid plus 20 grams of grinding powder plus 200 milliliters of dirty gasoline, and put the white corundum micro powder into the grinding glass bottle for more than 7 days.

SEARCH

PRODUCT LIST

Menu