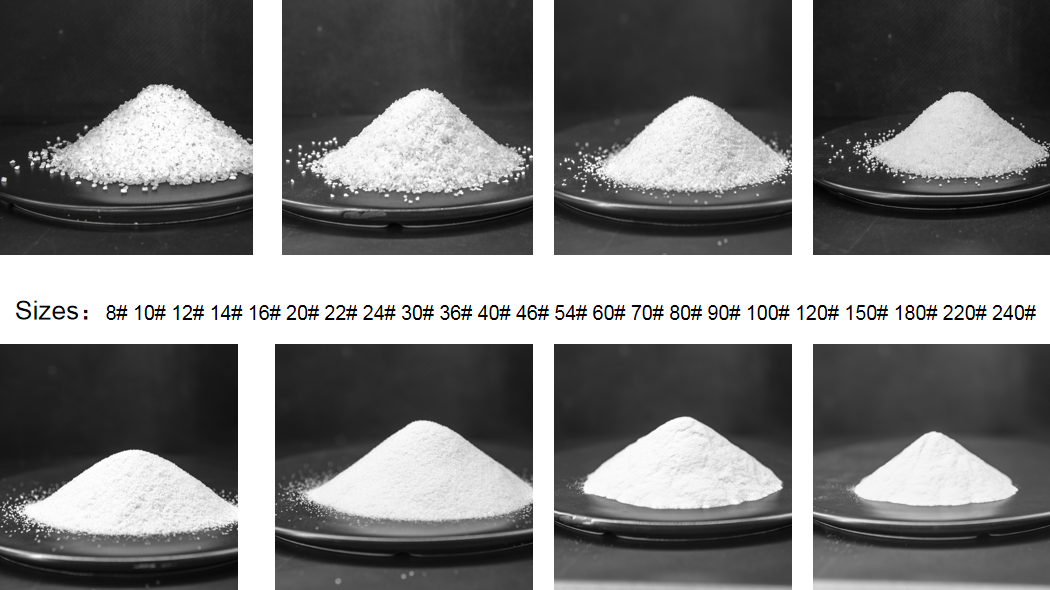

Surface cleaning metal preparation uses white fused alumina F60 F80 F100

Wfa glass sandblasting white fused alumina stainless steel sandblasting. with the eye-catching white color and the advantage of high density and low micro porosity, it can effectively improve the volume stability and the thermal shock resistance of the material. It is the mainly raw material to produce middle or high level unshaped or shaped refractory material. It is applied to the unshaped refractory materials, such as refractory carstables for ladles, middle or high level iron runner casting material, gunning refractory and fabricate parts ect. It also can be used to kinds of corundum products, such as corundum bricks, corundum, mullite corundum, refining corundum perforated bricks, overall blowtorch and combined nozzle, side ceiling of the high temperature kiln, ect. All in all, it is widely used in steel, cement, ceramics, grinding material and petrochemical industries.

Aluminum oxide is used successfully for cleaning, deburring, surface finishing, rust removal and old paint coatings, preparing surfaces for subsequent anti-corrosion treatments with paint and primer at the highest quality standards.

| Purpose | Specification | Chemical Composition(%) | Magnetic material content(%)max | ||||

| Abrasives grade | Al2O3min | Fe2O3max | SiO2max | TiO2max | |||

| grain | 12-80# | 99 | 0.05 | 0.26 | 0.08 | 0.0023 | |

| 90-150# | 99 | 0.06 | 0.28 | 0.09 | 0.0021 | ||

| 180-220# | 99 | 0.08 | 0.30 | 0.10 | 0.0018 | ||

| micropowder | 240-10000# | 98.5 | 0.1 | 0.40 | 0.15 | – | |

| Refractory grade | Group Size | 0-1mm 1-3mm 3-5mm 5-8mm | 99 | 0.1 | 0.35 | 0.3 | – |

| Fine Powder | -100mesh -200mesh -350mesh | 99 | 0.1 | 0.35 | 0.3 | – | |

| color | white | ||||||

| Hardness(mohs) | 9.0 | ||||||

| Melting point(°C) | 2250 | ||||||

| Maximum service temperature(°C) | 1900 | ||||||

| Ture density(g/cm3) | 3.9 | ||||||

White corundum white fused alumina application:

1.For precision casting and high-grade refractory.

2. For bake lining ,Catalyst carrier ,friction products

3.For pressure blasting hard abrasives;Refractory industry

4.For wet and dry blasting ,grinding,lapping and polishing media

5.For abrasive tools: grinding wheel, Lapping and polishing non-skid title;

6.For bonded and Coated abrasives ,Thermal Spraying (Plasma Spraying)

7.For lapping & Micro-Blasting applications .refractories,Ceramics and Tiles .