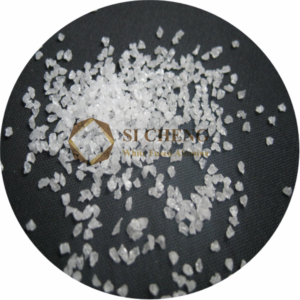

99.5% high purity refractory white fused alumina

White-fused alumina is the main raw material for the production of unshaped and shaped refractory materials.

1, High hardness and dense particles. Single-particle roundness is good.

2, The color is pure white, with no impurities, to ensure the wear-resistant layer or wear-resistant paper color and transparency.

3, Uniform distribution of particle size, single-particle shape consistent, with a small amount of wear-resistant effect.

4, Chemical stability and acid, alkali no action, high-temperature stability is very good.

Properties/type | 0-1mm, 1-3mm, 3-5mm | 0-100, 0-200, 0-320mesh | |||

Guarantee Value | Typical Value | Guarantee Value | Typical Value | ||

Chemical composition | AI2O3 | 99.0 min | 99.5 | 98.5min | 99.0 |

SiO2 | 0.4 max | 0.06 | 0.3max | 0.08 | |

Fe2O3 | 0.2 max | 0.04 | 0.2max | 0.10 | |

Na2O | 0.4 max | 0.30 | 0.4max | 0.35 | |

Test items | indicators |

Mohs hardness | 9.0 |

Bulk density | 1.75-1.95g/cm3 |

Real density | 3.95g/cm3 |

Melting point | 2250℃ |

The highest operating temperature | 1900℃ |

hite fused alumina, white fused alumina, white fused alumina, white fused alumina.

1. White fused alumina Commonly used in ladle castables, iron runner materials, refractory gunning mix materials and other monolithic refractory products;

2. For the shaped refractory materials, white fused alumina is mainly used in the high-quality raw materials of corundum brick, corundum mullite, refining steel porous plug brick, integral spray gun, steelmaking and continuous casting industry.

3. White fused alumina also can be used as materials for polishing, precision casting, spraying and coating, special ceramics and high-grade refractory materials,etc.